The Price of a Name

Every tender package contains hundreds of product choices. Some are made for technical performance, others for warranty alignment or procurement convenience. But many are made for one simple reason: habit.

Our latest pricing analysis reveals just how much those habits can cost. Across multiple product categories, we found products offering identical performance and compliance varying in price by over 50%.

In other words, teams are often paying more for the same outcome – not for better specification, just a better-known logo.

Example 1 – Floor Insulation: Identical Performance, Different Price

We compared three of the UK’s most specified 100 mm PIR floor insulation boards – all delivering the same U-value of 0.22 W/m²K and fully compliant with Building Regulations.

Technically, they are indistinguishable in performance: same thermal conductivity, compressive strength, and BRE rating. Yet the premium product costs 55% more.

Applied to a typical 200m² floor area, that’s a £1,000+ difference in material cost alone – before fabrication, labour or overheads are added.

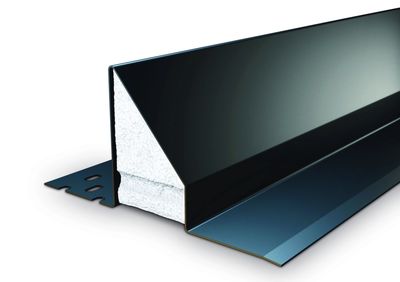

Example 2 – Steel Lintels: A Familiar Brand, a Familiar Pattern

Steel lintels tell the same story.

The Catnic CG90/100 is the UK’s most-specified lintel, stocked by nearly every major merchant.

We went out for pricing to five suppliers – Lawsons, Travis Perkins, Elliotts, London Lintels and Wade – for a standard 2.1m lintel.

The results:

- Catnic prices ranged £127–£247 ex VAT.

- Equivalent IG Lintels were ≈ 12 % cheaper on average.

- Birtley Lintels, also structurally equivalent, ranged from £86 to £112 ex VAT – around 42% cheaper overall.

For just five lintels on a modest project, that’s a saving of around £360 + VAT, with no change in specification or structural performance.

why this happens

There are three main reasons these cost gaps persist:

1. Specification inertia

Many project teams reuse standard specification notes from previous jobs, assuming brand equals compliance.

2. Procurement visibility

Tenderers often price from nominal product codes without re-checking equivalence, so small differences in description or brand familiarity can drive large price variations.

3. Perceived risk

Contractors and consultants often associate well-known brands with lower liability – even when the performance data is identical.

Beyond this, there are few incentives for suppliers or contractors to highlight cheaper equivalents. Re-quoting alternatives takes time, can reduce margins, and may even make larger suppliers less competitive. Some merchants quote premium products but later supply an equivalent alternative without notification, benefiting from the margin difference.

This cycle reinforces an industry-wide “brand premium” – one that quietly inflates budgets and limits fair competition across the supply chain.

What It Means at Tender Stage

These differences might seem small, but they multiply quickly. When you add the effects of inflated steel tonnage, oversized foundations or complicated temporary works, the combined premium can account for 3–5% of total build cost.

That’s before factoring in the embodied carbon impact of unnecessary materials.

Identifying equivalence early brings transparency and data back into the hands of the Architect and Client, ensuring every pound and kilogram is justified and defending the project’s budget.

how fortify helps

By using Fortify to review tender packages between RIBA Stages 4 and 5, we uncover structural and material inefficiencies before they’re locked in.

The system analyses each element of the package – from the beam schedules to product references – and benchmarks them against up-to-date cost and carbon data.

In more than 85% of projects, Fortify finds measurable savings – often around 20% reductions in steel weight and 3% savings on total build cost.

Those efficiencies don’t come from redesigning the building. They come from identifying smarter, equivalent ways to achieve the same result.

Projects such as Frith, Blackheath and Heath prove the value of this approach, removing tonnes of unnecessary steel and concrete, shortening programmes and saving tens of thousands of pounds.

Every decision in a specification has a ripple effect on budget, carbon and programme. By sharing current market data and equivalent product insights, we help project teams make confident choices at tender stage and beyond.

Fortify turns that insight into action by partnering with architects, developers and contractors, enabling you to identify savings early and leverage this knowledge on each new project.

See how Fortify can support your Client and Project Team by either sending us a Tender Package or setting up a Teams call today.

© 2025 Re-Structured. All Rights Reserved.